All rights are reserved under the copyright of Yasuyuki Ayukawa (2023)

I am visiting companies challenging the global market with Japanese skills, Japanese quality, and Japanese craftmanship based on the tradition. I don’t know if the world has overtaken Japan or if Japan has declined, but in recent years, it is said that Japan’s position in the world is declining in various parts such as economy, society, and the quality of life. But is it really so? Japan still has world-class technology, traditions, and culture, and the value of these has been recognized in other parts of the global market thanks to the efforts of many companies pioneering the market in many countries. Furthermore, there are also new companies taking on the challenge with products and technologies, with their confidence and pride, to the world. In this series, I would like to introduce how such companies are challenging the global market.

In these new series of issues,

I am introducing

the vital actions

of entrepreneurs

in Saga, Kyushu – west end of Japan.

The approach is, again,

how to

get into

overseas market.

This time,

I would like to introduce

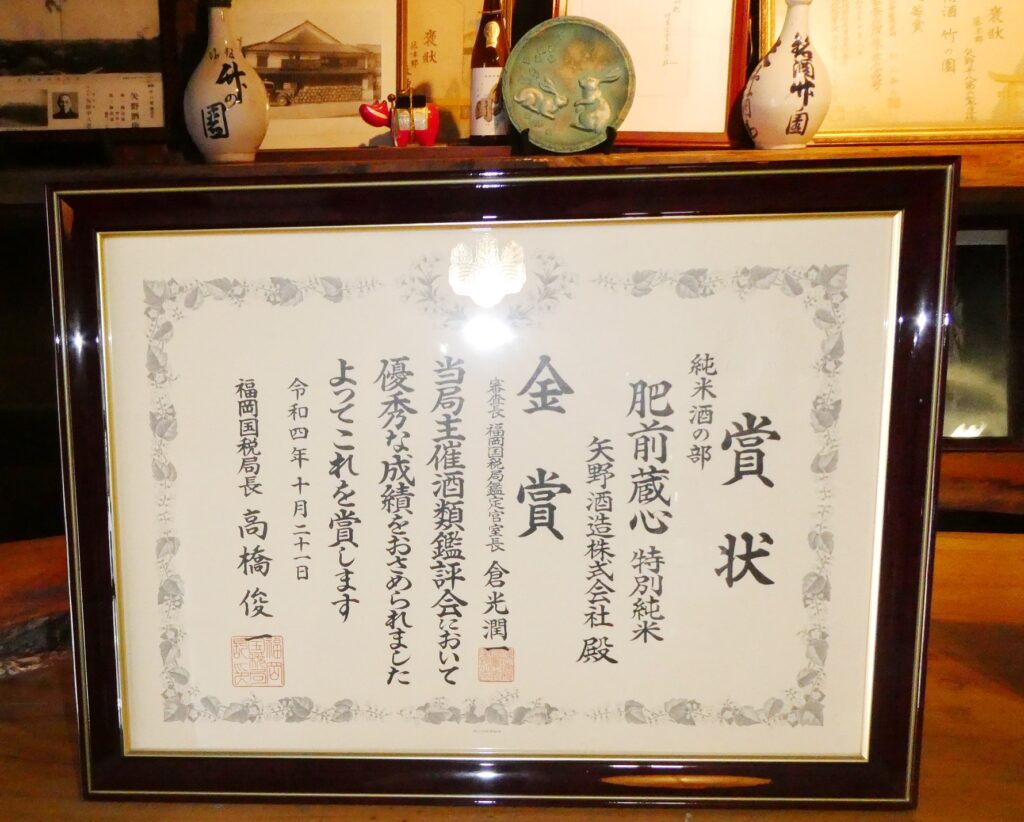

Yano Shuzo Ltd.

(https://yanoshuzou.jp)

Shuzo means

exactly

Sake Brewery

Thought to manufacture

Thought to brew

Mr. Motohide Yano, who I interviewed at this time, is the current owner of Yano Shuzo, as well as a toji, a chief brewer. It is from the previous generation that the family head can also serve as a toji.

Having the predecessor as the father, Mr. Motohide Yano, born into a family where the family business was inherited from generation to generation, did not inherit the family business straightforward.

Mr. Motohide Yano graduated a national university in Yokohama, and when he entered the university, he never thought about taking over the family business, but thinking of working for a trading company expanding businesses on global basis.

However, there are various stories, and Mr. Motohide Yano started to work at an art museum near the university just after graduating from university.

While working at a museum surrounded by the arts as the result of creation, Motohide-san turned his thoughts to making or manufacturing something, and decided to take over the family business. With such a story, Mr. Motohide Yano has a very strong desire to manufacture sakes as the results of his creation.

As president and toji, Mr. Motohide Yano enjoys being in charge of sake production, from design to brewing.

What is Yano Shuzo’s sake brewing design?

As a cornerstone of sake design, there is a sake with a lean and dry taste which is rare in Kashima. However, the taste of the market changes slightly every year. Also, the quality of rice changes every year, and therefore, the fermentation and brewing process also changes every year.

Saying simply, if the rice is hard even after steaming, it will be difficult to bring out the flavour of the fermented rice even if it is fermented, and the taste of sake will tend to be light. There is a tendency that it tends to have a pure taste.

The hardness or softness of the rice is influenced by the year the rice is produced.

The hard and soft finish of the rice is affected by the quality of the rice as crops, which chages year by year.

Therefore, Yano Shuzo is changing the type of yeast and the method of fermentation, by travelling forward and backward repetitively or alternatively, between the quality of rice which is fixed as the starting point, and the desired taste of the year. This is the way of Sake “manufacturing” by Mr. Motohide Yano of the year, as as toji, a chief brewer of Yano Shuzo.

Betting on Sustainability

in Sake Brewing

Yano Shuzo is also working on a “Take no Sono Goen,” which uses edible rice, cultivated in “Tanada”, a terraced rice field in Kashima city, instead of brewer’s rice.

This sake “Take no Sono Goen,” is made under the project created in collaboration with the Ramsar Convention Promotion Office of Kashima City and another sake brewery in Kashima city, actually nearby Yano Shuzo.

A connection among Sake, terraced rice fields, and the Ramsar Convention, unlikely seeming related one another at first glance. How did such a project come to fruition?

Sake rice is usually used Sake-rice, dedicated to make sake. It has large grains with a large core with rich carbohydrates. As a result, the purity of carbohydrates increases when polished, making it easier to make sake with refreshing tasted and little off-flavours. Yamada Nishiki is a typical example.

However, the degree of difficulty of rice cultivation increases accordingly. Sake rice, which has been around for a long time, is particularly tall and difficult to make because of its large size and weight. In addition, it is easy to fall down in strong winds and typhoons which hits Kyushu Island more and more often, maybe due to recent global warming. In fact, Kyushu is now hit by large typhoons every year.

The typhoon season is exactly the time when the ears of rice grow and the fruits grow. There is a concern that more farmers may leave from rice cultivation in Kyushu.

This is especially true for sake rice and terraced rice fields, where is located in mountainous area, requiring more labour-intensive cultivation than in a flat area.

On the other hand, terraced rice fields are said to have a natural buffer effect against landslide disasters, and are considered to play an important role in protecting tidal flats, preventing soil and sands carried into the tidal flats of the Ariake Sea, which were registered as wetlands under the Ramsar Convention in 2015.

Kashima City is working as an administration to protect this tidal flat as a wetland. In order to continue rice farming in the terraced rice fields, the edible rice grown in the terraced rice fields is used to make sake.

For Yano Shuzo, in order to continue brewing sake in the future, it is important not to rely solely on sake rice, but to have a brand of sake made from edible rice, due to the increased difficulty of procuring sake rice more and more.

In fact, last year, due to a poor rice harvest in Japan, the market for sake rice became tight, and especially third-class or higher grade rice, which is necessary to make specific brands such as Junmai Ginjo, was in short supply. Yano Shuzo also had a hard time procuring rice.

This is how the sustainability of sake brewing, rice farming and rice terraces, and the tidal flats of the Ariake Sea are connected one another.

As I mentioned before, the head of the family, Mr. Motohide Yano, is also involved in the administrative work of the Kashima Gatalympics, the athletic meeting on the tidal flats.

This meeting, which has many participants from outside the city and prefecture, is also intended to enliven the tidal flats and raise awareness about the protection of the tidal flats.

Mr. Motohide Yano said that even if he did not participate in the competition, he could not leave the tidal flats for more than 6 hours during ebb tide.

In 2023, it was held on 4th of June as reopened after Corona.

The demand for sake in Japan is definitely falling. As I said before, there used to be 20 sake breweries in Kashima City, but now the number has been reduced to 5, including Yano Shuzo.

Yano Shuzo’s way of

being as a sake brewery,

which finds a way out of

export by betting

on the sustainability of

sake brewing,

I would like to pay attention to it along with its distinctive taste.

All rights are reserved under the copyright of Yasuyuki Ayukawa (2023)